Galvanized Steel Coils Manufacturer/ Supplier From Vietnam

GTS Steel is one of the best galvanized steel coils supplier in Vietnam, our galvanized steel coil production line has an annual production capacity of 300,000 tons and a manufacturing on moden production line. We can manufacture galvanized steel coils with a width of 800-1250mm and a coating weight of 60-300g/m3.

We manufacture galvanized steel coils according to EN 10346, ASTM A653 standard. We have sufficient galvanized steel sheet in coils with soonest delivery.

Hot Dipped Galvanized Steel Sheet in Coil (or GI steel coils) is produced by passing the Full Hard sheet which has undergone the acid washing process and rolling process through the zinc pot, thereby applying zinc film to the surface. It has excellent corrosion resistance, paintability, and workability due to Zinc’s characteristics.

Usually, hot-dipped galvanized steel sheet and galvanized zinc coated steel coil process and specifications are basically the same.

Surface Structure

| Surface Structure | Zero Spangle | Big Spangle |

| Weight of zinc coating | Zinc > 20g/sm | Zinc > 30g/sm |

| Surface Finish |  |

|

Spangled galvanized zinc coated steel sheet in coils is the spangle obtained by the condensation of the zinc coating under normal conditions after galvanizing. It is mainly used in buildings and other places where there is little direct contact with the human body.

Our galvanized steel sheets without spangles are mainly produced through a special production process to control the lead in the zinc pot to a certain level, or after the strip steel is out of the galvanized pot, it undergoes special treatment to control the spangles to less than a certain level. Mainly used in home appliance housing.

Hot Dipped Galvanized Steel Coil Manufacturer In Vietnam – GTS Steel

The production and processing of galvanized steel coils can be divided into three steps: first, the entire coil is pickled to remove rust and dirt, so that the surface of the galvanized steel strip can achieve a bright and clean effect; after pickling, pass ammonium chloride or zinc chloride It is cleaned in an aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the hot-dip plating tank for the galvanizing process; after the galvanizing process is completed, it can be put into storage and packaged.

Surface Treatment Of Galvanized Steel Coil

| Surface treatment type | Code | Feature |

|---|---|---|

| Chromic acid treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic acid treatment + oiling | S | Good corrosion resistance |

| Phosphoric acid treatment (including sealing treatment) | P | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (including sealing treatment) + oiling | Q | It has certain corrosion resistance, good paint performance, and prevents rust during transportation and storage |

| Phosphoric acid treatment (excluding sealing treatment) | T | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (excluding sealing treatment) + oiling | V | Have certain corrosion resistance, good paint performance, and prevent rust |

| Oiled | O | Prevent rust during transportation and storage |

| No treatment | M | Suitable for immediate painting |

Chromate treatment of galvanized steel coils is also called passivation treatment. Through passivation treatment, the surface structure and gloss of the galvanized layer can be improved, the corrosion resistance and service life of the galvanized layer can be improved, and the bonding force of the coating and the base metal can be improved.

The purpose of oiling galvanized steel coils is a protective layer is formed on the surface of the steel coil to prevent the surface from rusting.

Types Of Zinc Coating Of Galvanized Steel Coils Produced In Vietnam

Hot-dip galvanized coils are divided into pure zinc coating and zinc-iron alloy coating according to the coating. Their common point is that the zinc content of the zinc solution in the zinc pot is the same. The difference is that the zinc-iron alloy adds an alloying process.

Pure Zinc Coating

In the hot-dip galvanizing production line, the pre-treated steel strip is immersed in the molten zinc bath to obtain the coating. The zinc content in the molten zinc solution should not be less than 99%.

Zinc-Iron Alloy

A zinc-iron alloy layer is formed on the entire coating through an alloying treatment process, and the iron content in the alloy coating is usually 8-15%. During the alloying process, the galvanized steel coil is heated to 550-560°C in an alloying furnace in 5-10 seconds, so as to convert all the pure zinc layer into iron-zinc alloy. Its weldability, coating performance, heat resistance, and corrosion resistance are better than ordinary galvanized sheets.

For example:

EN 10346 DX51D+Z is pure zinc;

EN 10346 DX51D+ZF is zinc-iron alloy coating.

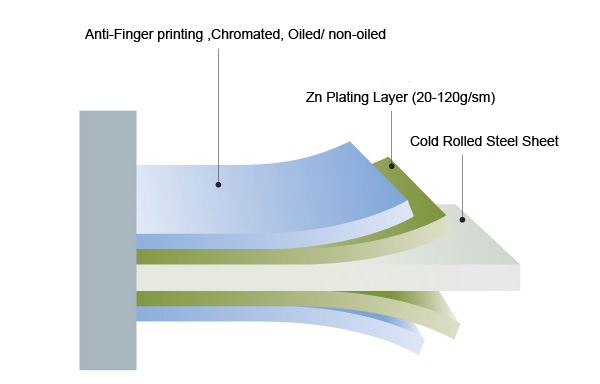

Galvanized Coating Layer

- Anti-Finger printing ,Chromated, Oiled/ non-oiled

- Zn Plating Layer (20-120g/sm)

- Cold Rolled Steel Sheet

See more:

American ASTM A653 Standard Galvanized Steel Sheet & Coils

- Commercial Steel (CS Types A, B, and C)

Commercial Steel is a low-carbon cold-formed steel, such as galvanized steel roof forming

- Forming Steel (FS Types A and B)

Requires higher drawability than Commercial Steel, such as for lamp cover forming

- Deep Drawing Steel (DDS)

- Extra Deep Drawing Steel (EDDS)

- Structural Steel (SS) – (33,37,40,50,80)

- High Strength Low Alloy Steel (HSLAS)

European EN 10346 Standard Galvanized Steel Coil

Low carbon steel for cold forming (DX51D – DX54D)

- DX51D is equivalent to Commercial Steel, curved and profiled

- DX52D is equivalent to Forming Steel

- DX53D is equivalent to Deep Drawing Steel

- DX54D is equivalent to Extra Deep Drawing Steel

Structural Steels (S220GD – S350GD)

S220GD,S250GD,S280GD,S320GD,S350GD

Use structural steel for high load-bearing capacity, with a yield strength of 220-350

Visit our coated steel coils mills (galvanized/ galvalume/ prepainted steel coils ) factory in Vietnam:

About Us - GTS Steel

As a Steel Supplier/ Steel Sourcing/ Business Consult company, our mission is to connect you with suitable leading steel manufacturers in Vietnam and China, to support you to get the best quotation from reliable steel manufacturers.

For over 10 years in steel field, GTS Steel have set up deep connections with steel manufacturers/ steel mills in Vietnam and China. We are confident to bring the best price and service to our customers with various types of steel products:

- Hot Rolled Coils steel - HRC

- Cold Rolled Coils - CRC

- Coated Steel (Galvanized steel/ Galvalume steel coils, Prepainted Steel Coils - GI, GL, PPGI, PPGL)

- Wire rods, Beams

- Stainless steel

- Steel pipes...

We believe that our sourcing services will help you to find the right manufacturers with qualified quality steel products and best competitive prices.

If you are looking for steel coils products from leading steel manufacturers in Vietnam and China, please feel free contact us at:

Bài viết liên quan

GI, GL, PPGI, PPGL Steel Manufacturers In Vietnam – Ton Dong A

Ton Dong A extends a warm welcome as a distinguished leader in Vietnam’s steel manufacturing

Get A Quote

Please fill your requirements in here, we will get back to you at soonest.

GI, GL, PPGI, PPGL Steel Manufacturer In Vietnam – Ton Phuong Nam (SSSC)

Ton Phuong Nam (SSSC) stands as a leading GI, GL, PPGI, and PPGL steel manufacturer

PPGI and Galvanized Steel Coil (GI) Manufacturers In Vietnam

List Of PPGI and Galvanized Steel Coils Manufacturers In Vietnam: Vietnam is know as one

Leading Galvanized Steel Coils Manufacturer From Vietnam – Introduction About Hoa Sen Group

In the dynamic world of construction and manufacturing, the reliability and durability of materials like

What is RMP, SMP, SDP and PVDF Paint Type of PPGI, PPGL Steel Coils ?

What is different between paint types: RMP, SMP, SDP and PVDF on prepainted color coated