What is Galvanized Steel Coils ? Definition of Galvanized Steel Coils. Find your galvanized steel coils manufacturer/ supplier from Vietnam.

What is Galvanizing in Steel production?

Galvanizing, or galvanization, is a manufacturing process where a coating of zinc is applied to steel or iron to offer protection and prevent rusting.

There are several galvanizing processes available, but the most commonly offered and used method is called hot-dip galvanizing in steel industry.

Galvanized steel is among the most popular steel types because of its extended durability, having the strength and formability of steel plus the corrosion protection of the zinc-iron coating.

The zinc protects the base metal by acting as a barrier to corrosive elements, and the sacrificial nature of the coating results in a long-lasting and high-quality steel product.

This versatility makes it applicable to a variety of projects and industries, including agriculture, solar, automotive, construction, and so on. Below, we aim to provide a comprehensive description of how galvanized steel is processed, different galvanization methods, its benefits, and how it is used in these various industries.

The steps in the galvanizing process are as follows:

- The steel is cleaned in a degreasing solution

- After being cleaned, the steel is pickled by being lowered into a vat of diluted hot sulfuric acid

- The steel is then fluxed in an aqueous solution (typically zinc-ammonium chloride)

- After the flux, the steel is galvanized through immersion in a vat of molten zinc

- Afterward, the steel is inspected for consistency and a complete coating

Application of Galvanized Steel Sheet In Coils:

Galvanized steel coil and sheet products are now being used for a wide range of electric appliances, automobiles and other industrial machinery as well as for civil engineering and architectural purposes.

As nations industrialize worldwide, galvanized steel coils and sheets are becoming vital materials for the development of modern societies today. Consumers today are increasingly demanding larger quantities and higher quality of steel products, leading to the advancement, diversification, and functional enhancement of these products.

By looking through this, galvanized steel sheets in coils are finding an increasing range of applications, including a range of civil engineering construction projects as well as automobile and home appliance manufacturing. These sheets boast great resistance to corrosion as well as ease of working, welding, and painting.

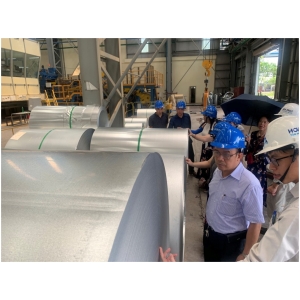

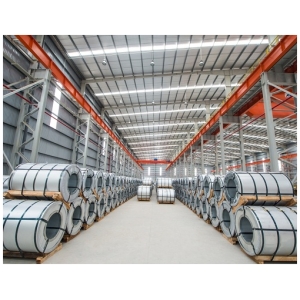

Our galvanized steel coil and sheet is produced using the latest automatic factory system and boasts the excellent quality of customers require. We are working hard to provide premium-quality steel products that meet consumers’ needs and expectations. This content is for informational purposes only. The packaging is not included in the LCA study.

Some Images of our Galvanized Steel Coils Products in our factory in Vietnam:

What are the advantages of galvanized steel sheet in coils?

Many different industries uses galvanized steel coils primarily because it has such a wide range of benefits for industries to take advantage of, including having:

Low initial cost compared to most treated steels. In addition, galvanized steel coils is immediately ready to use when delivered. It does not require additional preparation of the surface, inspections, painting/coatings, etc. sparing companies more costs on their end.

Longer life. With galvanization, a piece of industrial steel is expected to last more than 0 years in average environments, and can last over 20 years with severe water exposure. There is no maintenance required. The increased durability of the steel’s finished product also increases the product’s reliability.

The sacrificial anode ensures that any damaged steel is protected by the surrounding zinc coating. It doesn’t matter if the steel section is completely exposed; the zinc will still corrode first. The coating will corrode preferentially to the steel, creating a sacrificial protection to the areas that are damaged.

Rust resistance from the zinc coating. The iron elements in steel are incredibly prone to rusting, but the addition of zinc acts as a protective buffer between the steel and any moisture or oxygen. Galvanized steel is very protective, including sharp corners and recesses that couldn’t be protected with other coatings, making it resistant to damage.

Different methods of galvanizing

As stated above, there are several different processes for galvanized steel coils.

Hot-Dip Galvanizing – What is hot-dip galvanized steel coils products ?

The first and foremost method for galvanization is hot-dip galvanizing. The process is very similar to what the name suggests! In this method, steel or iron is dipped in a molten pool of zinc that maintains a temperature of around 860°F (460 °C).

This molten bath begins a metallurgical bond between the zinc and the receiving metal. After the metal is pulled from the bath, it reacts to being exposed to the atmosphere, and the pure zinc mixes with oxygen to form zinc oxide.

The zinc-oxide further reacts to carbon dioxide and forms zinc carbonate, which makes up the final protective coating on the material. The tell-tale sign of a hot-dipped galvanized material is the presence of a crystalline-like pattern on the surface, sometimes referred to as “spangle.”

Visit our Galvanized Steel Mill In Vietnam:

About Us – GTS Steel

GTS Steel is engaged as Steel Supplier (Exporter) as well as agent of top largest steel manufacturers in Vietnam and China.

Our mission is to connect you with suitable leading steel manufacturers, to support you to get the best quotation from reliable steel manufacturers.

For over 10 years in the steel field, GTS Steel have set up deep connections with steel manufacturers/ steel mills in Vietnam and China, our steel products are exported to over 50 countries.

We are confident to bring the best price and service to our customers with various types of steel coils products:

- Galvanized Steel Sheet In Coils (GI coils)

- Galvalume Steel Sheet In Coils (GL coils)

- Prepainted Galvanized Steel Sheet In Coils (PPGI)

- Prepainted Galvalume Steel Sheet In Coils (PPGL)

If you are looking for steel coils products from leading steel manufacturers in Vietnam and China, please feel free contact us at:

GTS Steel Pacific Ltd

🏢 Address: 2B NTMK, Dakao Ward, District 1, HCM City, Vietnam

📞 Mobile/Whatsapp/Wechat: +84 907 112 447

📞 Whatsapp: https://wa.me/+84907112447

📧 Email: enquiry@gtssteel.com

🌏 Website: https://gtssteel.com/

Bài viết liên quan

What Is Galvanized Steel Coils ? All About Galvanized Steel Coils

What Is Galvanized Steel Coils ? (GI Steel Coils) Galvanized steel coils are sheets of

Top 5 Galvanized Steel Manufacturers In Vietnam

Vietnam is one of the leading countries producing and exporting steel in the world (combine

Top 10 Largest Coated Steel Coils (GI, GL, PPGI, PPGL) Manufacturer In Vietnam

Top 10 Largest Coated Steel Coils Manufacturer In Vietnam – GI, GL, PPGI, PPGL Steel

New global quotas, Vietnam included in hot dipped galvanized steel coils (HDG) quota

The EU has informed the World Trade Organisation (WTO) of its decision to extend steel

Galvanized Steel Coils Supplier From Vietnam – GTS Steel

Find your Galvanized Steel Coils manufacturer/ supplier from Vietnam. We are GTS Steel, specialized on

Top 5 Leading Galvanized Steel Coils Manufacturer In Vietnam

Vietnam have some big steel mills who produce and exported huge quantity coated steel sheet