Galvanized steel coils is represented by cold- and hot-rolled coils with a zinc coating, which helps to protect the steel against atmospheric corrosion.

Galvanized steel sheet in coils (or HDG coated steel coils) are successfully used in industries with stringent requirements for corrosion resistance, durability, strength and appearance, and can be formed or have various coatings applied.

The key standards to be followed for the production of our galvanized steel coils include EN 10346 (Europe), ASTM A653 / A653M (US), DSTU EN 10346 (Ukraine), GOST 14918−80 (Russia and the CIS) and GOST R 52246−04 (Russia). Manufacturers also have their own original standards.

Our galvanised steel coils are widely used in the following industries:

-

In the construction industry: to manufacture structural elements low-rise construction, light steel thin-walled structures, sandwich panels, lining of heat pipelines and various heat insulation, conditioning systems, metal roof shingle, profiled sheeting, culvert pipes, cladding of entry doors, elevators, reinforcement profiles for PVC windows and plastic doors, European-type fasteners for plasterboards, etc

-

In the automotive industry: to manufacture external and internal car body parts, as well as to repair external public transport body parts, eg for buses and trams)

-

In the machine building and instrumentation industries: to manufacture cases for electrical and mechanical equipment, home appliances, metering devices and packing

-

To manufacture houseware (tableware, bowls, buckets, tanks, baths, etc)

-

To manufacture prepainted steel coils (and other type of coating) rolled steel

HDG steel coil classification, product range and properties

Standards applied in different countries to set the requirements for galvanized steel sheet in coils specify steel grade and size ranges for these products. Galvanized steel coils are classified based on the following features:

-

Application of coated steel coils (profiling, cold forming, manufacture of steel structures)

-

Chemical composition of coating material (pure zinc, zinc-iron/zinc-aluminium/aluminium-zinc/zinc-magnesium alloys, etc)

-

Thickness/weight of protective coating.

HDG coils according to European standards

Galvanised steel coils as per the European EN 10346 and the similar Ukrainian DSTU EN 10346 standards can be coated with zinc, zinc-iron alloy, zinc-aluminium alloy, aluminium-zinc alloy or aluminium-silicon alloy:

-

Zinc coating (Z) is achieved by dipping the prepared strip into a bath with molten alloy, containing at least 99% zinc. This is the most common and traditional way of protecting rolled steel from corrosion.

-

Zinc-iron coating (ZF) is formed by dipping a strip into a bath of molten zinc (at least 99% zinc) with further annealing to form a zinc-iron coating with an Fe content of 8-12%. Such coating is stronger than the traditional zinc coating and has better adhesion with substrate steel due to mutual diffusion between the iron and zinc in the surface layers. That is why this coating is less exposed to lamination or pitting under impact, mechanical stresses or deformation of treated products.

-

Zinc-aluminium coating (ZA) is applied to rolled steel by dipping it into a bath of zinc and about 5% aluminium with a minor content of mishmetal (mix of metals). Rolled steel with such coating has better formability and corrosion protection properties compared with zinc-coated steel.

-

Aluminium-zinc coating (AZ) is applied by dipping steel into a bath of molten metal consisting of 55% aluminium and 1.6% silicon (with the remaining being taken up by zinc). The combined action of these metals ensures the best corrosion protection compared with other coatings.

-

Aluminium-silicon coating (AS) is created by dipping steel into a bath of molten metal containing aluminium and 8-11% silicon. Galvanized steel coil with such coating is highly resistant to oxidation at high temperature (up to 650°C) and highly resistant to chemical corrosion.

Galvanised steel coils manufactured according to the EN 10346 and DSTU EN 10346 standards can be made from the following steels:

| Coating designation | Minimum total coating weight for both surfaces, g/m2 | Theoretical recommended values of the coating thickness per unit of surface for single-spot tests, microns | Density,

g/cm3 |

||

| Three-spot | Single-spot | Reference value | Interval | ||

| Z100 | 100 | 85 | 7 | 5-12 | 7.1 |

| Z140 | 140 | 120 | 10 | 7-15 | |

| Z200 | 200 | 170 | 14 | 10-20 | |

| Z225 | 225 | 195 | 16 | 11-22 | |

| Z275 | 275 | 235 | 20 | 15-27 | |

| Z350 | 350 | 300 | 25 | 19-33 | |

| Z450 | 450 | 385 | 32 | 24-42 | |

| Z600 | 600 | 510 | 42 | 32-55 | |

Galvanised steel coils as per the EN 10346 standards are also classified based on:

-

Types of surface quality:

-

А – surface quality right after coating application

-

В – surface quality improved by processing in a skin pass mill

-

С – highest surface quality also obtained by processing in a skin pass mill; the controlled surface should allow for the application of a homogeneous layer of decorative paint, while the other surface should have minimum quality B

-

-

Surface treatment:

-

Chemically passivated – С

-

Oiled – О

-

Passivated and oiled – СО

-

Phosphate treated – Р

-

Coated with organic insulation – S

-

-

Surface finishing:

-

Standard spangle pattern (normal gloss) N is obtained by allowing zinc coating to harden naturally

-

Minimum spangle pattern (minimum gloss) M is obtained by adjusting molten zinc composition and special measures for hardening and/or subsequent surface finishing

-

Geometry and size tolerances for steel sheets and strip coated by hot dipping should meet the requirements of the European EN 10143 standard and its Ukrainian analogue DSTU EN 10143.

See more:

GI GL PPGI PPGL manufacturer, supplier from Vietnam.

HDG coils according to US standards

The main US standard followed for the production of hot-dip galvanized coils with metallic coating is ASTM A653/A653M.

Galvanised products can be produced from the following steels:

-

Commercial steel (CS, types А, В and С)

-

Formable steel (FS, types А and В)

-

Deep drawn steel (DDS)

-

Structural steel (SS)

-

High-strength low-alloy steel (HSLAS, types А and В)

-

Solution hardened steel (SHS)

-

Bake hardenable steel (BHS)

Depending on the class of selected zinc coating (G01-G360 for British Imperial system, or Z001-Z1100 for international system of units SI), the minimum weight of protective material can vary from 90 tо 1,100 g/m2 on both sides of the product.

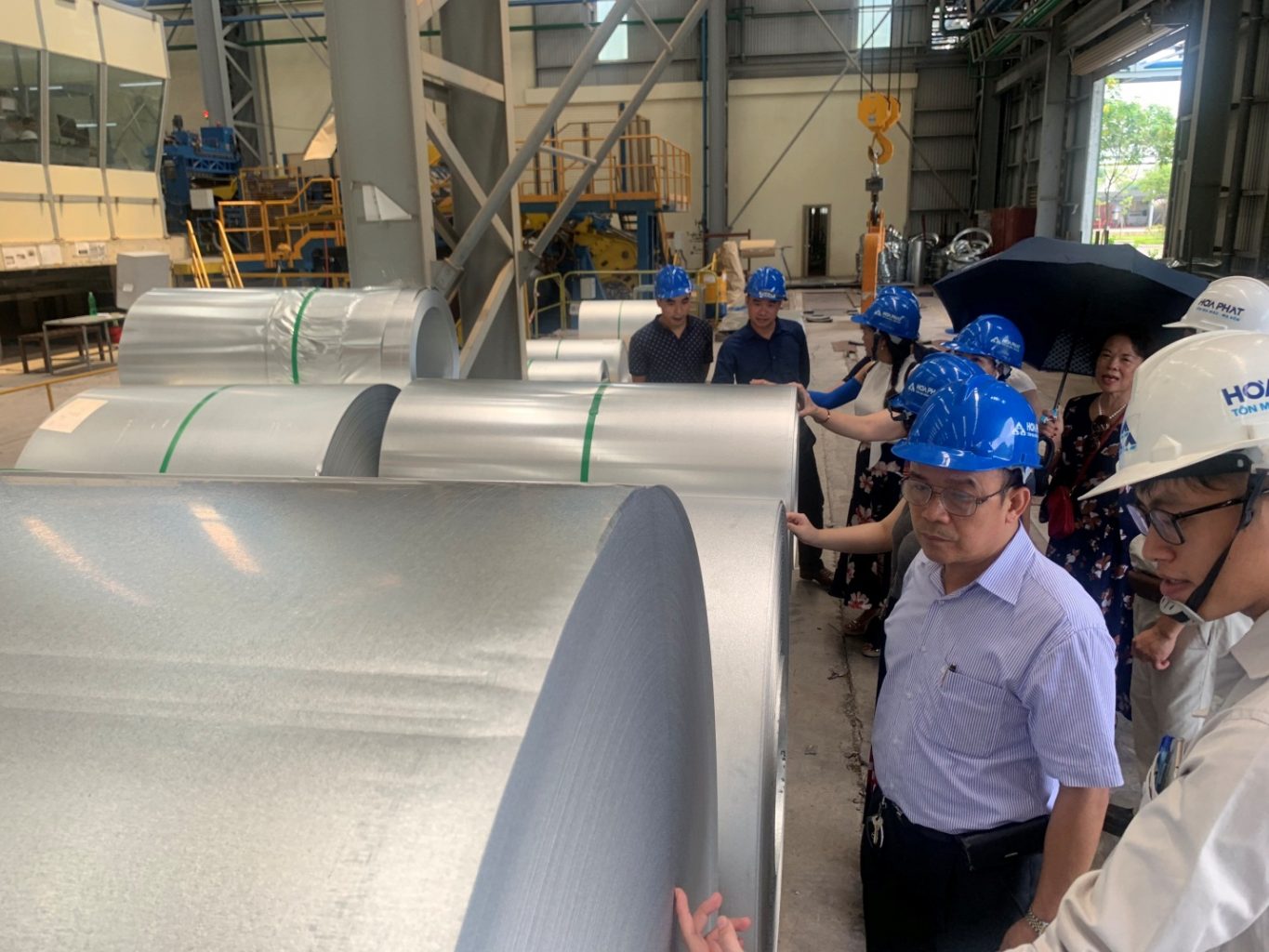

Production of galvanised steel coils

There are two widely used methods for applying zinc coating on steel coils:

-

Hot-dip galvanising (HDG) technology is used to create a protective layer by immersing a steel strip into a bath of molten zinc. Hot-dip galvanised steel coils can be produced by continuous galvanising lines with non-oxidising annealing furnaces (the Sendzimir method and its variations) or by applying wet or dry flux (the Cook-Norteman method and its modifications). Hot- or cold-rolled non-annealed (full-hard) steel coils are used as feedstock for continuous hot-dip galvanising lines with non-oxidising annealing furnaces.

-

The production process involves electrochemically cleaning, drying and annealing the strip to obtain the required mechanical properties, followed by immersing the material into a bath of molten zinc and controlling zinc thickness. The strip then undergoes forced cooling and finishing (passivation, oiling, levelling, drying and coiling the galvanized coil). When using lines that apply wet or dry flux, feedstock (before it is galvanized) should have the required set of mechanical properties since such lines do not have annealing furnaces.

-

The strip is first degreased with an alkali solution and pickled in acid, following which a smooth layer of flux composed of a combination of zinc chloride, ammonia chloride and various additives is applied to the strip. The strip is then put into a strand furnace with a protective atmosphere, where the flux is dried, and is immersed into a bath of molten zinc. The flux completely removes residual pickling substances and moisture from the metal surface, and the thin film reduces the surface tension of zinc and ensures the best moistening of the metal surface. Hot-dip galvanising technology is fairly universal and is widely used in construction, machine building and other industries. It is used by both large steel mills and re-rollers/coaters.

-

Electrolytic galvanising is an electro-chemical process in which a layer of zinc is applied in a bath of acid or alkali electrolytes. The main idea of this technology is to use oxidising and reducing reactions, during which electrons move through the electron transport chain, while zinc ions in the electrolyte flow from anode to cathode.

-

This type of coating is usually used for thin-gauge material; the coating thickness is normally 5-12 μm and it accurately follows the shape of the product. The absence of intermediate brittle layers makes electrolytic zinc coating more plastic compared with coating applied via hot-dip galvanizing. Major application areas for such products include automotive, transport and machine building, among others.

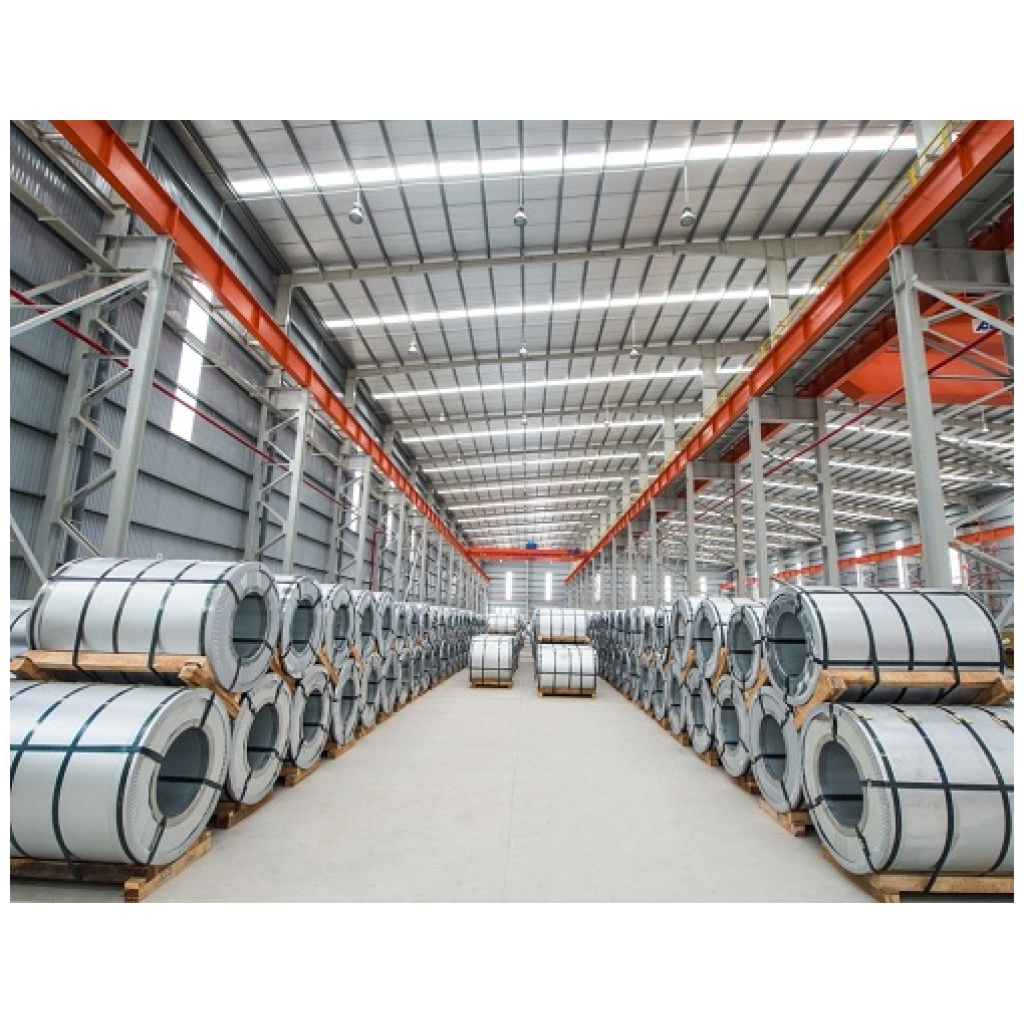

Buy galvanized teel coils from the manufacturer in Vietnam:

VSS Steel offers galvanised steel coils with a thickness of 0.4-2.0 mm and a width of up to 1,250 mm for construction and machine building applications, roofing.

Our galvanized steel coils products are supplied in accordance with the requirements of key international standards (EN 10346, ASTM A653/A653M, GOST 14918, GOST R 52246).

About Us – GTS Steel

As a Steel Supplier/ Steel Sourcing/ Business Consult company, our mission is to connect you with suitable leading steel manufacturers in Vietnam and China, to support you to get the best quotation from reliable steel manufacturers.

For over 10 years in steel field, GTS Steel have set up deep connections with steel manufacturers/ steel mills in Vietnam and China. We are confident to bring the best price and service to our customers with various types of steel products:

– Hot Rolled Coils steel – HRC

– Cold Rolled Coils – CRC

– Coated Steel (Galvanized steel/ Galvalume steel coils, Prepainted Steel Coils – GI, GL, PPGI, PPGL)

– Wire rods, Beams

– Stainless steel

– Steel pipes…

We believe that our sourcing services will help you to find the right manufacturers with qualified quality steel products and best competitive prices.

If you are looking for steel coils products from leading steel manufacturers in Vietnam and China, please feel free contact us at:

Bài viết liên quan

What Is Galvanized Steel Coils ? All About Galvanized Steel Coils

What Is Galvanized Steel Coils ? (GI Steel Coils) Galvanized steel coils are sheets of

Top 5 Galvanized Steel Manufacturers In Vietnam

Vietnam is one of the leading countries producing and exporting steel in the world (combine

Top 10 Largest Coated Steel Coils (GI, GL, PPGI, PPGL) Manufacturer In Vietnam

Top 10 Largest Coated Steel Coils Manufacturer In Vietnam – GI, GL, PPGI, PPGL Steel

New global quotas, Vietnam included in hot dipped galvanized steel coils (HDG) quota

The EU has informed the World Trade Organisation (WTO) of its decision to extend steel

Top 5 Leading Galvanized Steel Coils Manufacturer In Vietnam

Vietnam have some big steel mills who produce and exported huge quantity coated steel sheet

What Is Galvanized Steel Coils ?

What is Galvanized Steel Coils ? Definition of Galvanized Steel Coils. Find your galvanized steel